En la industria del hardware, los componentes pequeños como chinchetas, tornillos, remaches y arandelas Pueden parecer insignificantes, pero afectan directamente la calidad del producto y la experiencia del cliente. La clasificación manual tradicional es ineficiente, propensa a errores y costosa. Con tecnología avanzada de imágenes y reconocimiento de IA, Clasificador de color GroTech Ofrece clasificación y eliminación de defectos de alta eficiencia, lo que ayuda a los fabricantes a reducir costos, mejorar la eficiencia y construir una reputación de calidad estable y confiable.

En la producción de chinchetas, tornillos y otros herrajes pequeños, a menudo surgen problemas de calidad:

Colores inconsistentes afectando la apariencia general.

Impurezas o defectos superficiales reduciendo la satisfacción del cliente.

Ineficiencia en la clasificación manual , lo que requiere altos costos laborales y una precisión limitada.

Estos desafíos limitan la productividad y obstaculizan la consecución de una fabricación a gran escala y de alta calidad.

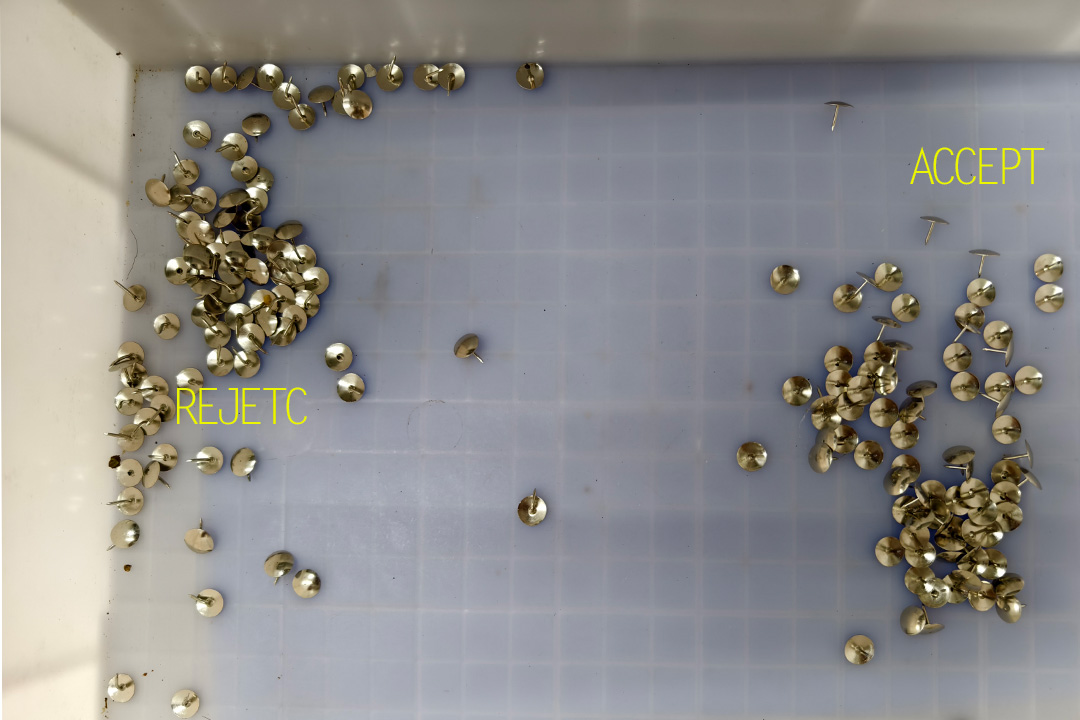

Equipado con imágenes ópticas avanzadas y algoritmos de inteligencia artificial, el clasificador de color GroTech puede detectar rápidamente Diferencias de color y defectos superficiales en chinchetas, tornillos, remaches y arandelas, retirando piezas defectuosas con tecnología de chorro de aire de alta velocidad.

Al garantizar que cada lote de piezas de hardware tenga un color y una apariencia uniformes, GroTech mejora la confiabilidad del producto y fortalece la confianza de la marca en los mercados competitivos.

Un clasificador de color GroTech puede reemplazar a varios trabajadores en la clasificación manual, lo que permite producción continua y automatizada que reduce significativamente los costos laborales y al mismo tiempo aumenta el rendimiento.

Más allá de las chinchetas, el clasificador de colores GroTech también es adecuado para tornillos, tuercas, remaches, arandelas y otros componentes de hardware pequeños, lo que lo convierte en una solución versátil para la industria de fabricación de hardware.

A medida que se acelera la automatización industrial, clasificación inteligente de hardware se ha convertido en una tendencia inevitable. Con su eficiencia, precisión y estabilidad, el Clasificador de color GroTech se está convirtiendo en el “guardián de la calidad” para cada vez más fabricantes de hardware.